Global impact

The thought

In 2002, William McDonough and Michael Braungart published a book “remaking the Way We Make Things”, which has had a major impact on companies worldwide, especially as regards sustainable product design.

A product is seen as the chain of origin (extraction of raw materials, production), use (energy consumption and consumption of excipients) and discarding (reuse and landfill). The so-called “Take-Make-waste” principle.

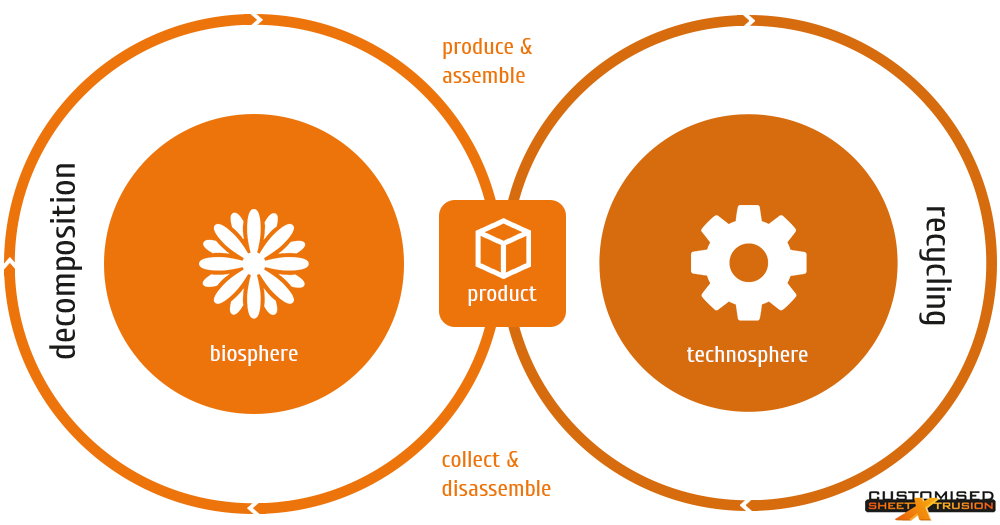

The central thought of the philosophy behind “cradle to Cradle” is that all materials used after their life in one product, can be usefully deployed in the same or another product. The big difference with conventional reuse (recycling) is that there is no quality loss (upcycling), and no residual products that are still deposited: “Waste equals Food”.

Cradle 2 cradle philosophy

In the technical cycle, reusability (and preferably upcycling) is the whole point. Both fossil plastics and biobased and even some biodegradable plastics are reusable. CSX has gained a lot of experience with the reprocessing of all the mentioned plastics and, thanks to the innovative production process, CSX has managed to recycle even the starch-based (TPS) plastics 100%.

CSX argues here that the traditional recycling (think of On the Second Life flow, which, admittedly, gives a second or third life to products, but not a solution for any resulting environmental pollution) is ideally Should be replaced by the upcycling principle.

Design for Disassembly

The starting point is that products or materials that are located in this cycle are 100% safe for the environment and are also well-degradable. In terms of standards and specifications, the EN13432 and EN14995 in Europe are already giving good encouragement.

CSX pays a lot of attention to the so-called hybridisation of end products in the chain (think of wood that is varnished and which is not well degradable and sometimes even downright bad for the environment.) and aims to influence and voluntarily Offered expertise to use throughout the value chain. For example, CSX gives an active form to the so-called “Design for Disassembly” principle.